ball indentation hardness test|metal dented after hardness test : bespoke Alternatively, methods with dynamic force application can also be used within the scope of hardness testing. These include, for example, the Leeb rebound hardness test method / Leeb hardness test (ISO 16589, ASTM A965), which . webAIDA64 Extreme is a streamlined Windows diagnostic and benchmarking software for home users. AIDA64 Extreme provides a wide range of features to assist in overclocking, hadware error diagnosis, stress testing, and sensor monitoring.

{plog:ftitle_list}

webO ESC online é referência em jogos de casino, mas pouco a pouco também vem se tornando um dos mais buscados em termos de apostas desportivas. Com ele é possível realizar diversos tipos de apostas que incluem competições como Premier League, .

An indentation hardness test is an excellent simulation of the very early stage of a penetration event, especially one involving a rigid, pointed projectile and a plastically deforming metal. It is .

The Brinell hardness test involves indenting a material with a hard sphere under a specific load. Two diameters (x and y axis) of the indentation are measured, and the hardness value is . Macroindentation tests are characterized by indentations loads L in the range of 2 N < L < 30 kN [10]. The main macroscale tests used by the industry and research .

The hardness of plastics and hard rubber can be determined using a loaded ball indenter in accordance with standard ISO 2039-1 or ISO 2039-2. Standard ISO 2039-1 describes .

Alternatively, methods with dynamic force application can also be used within the scope of hardness testing. These include, for example, the Leeb rebound hardness test method / Leeb hardness test (ISO 16589, ASTM A965), which .The Rockwell test consists of measuring the additional depth to which a carbide ball or Brale® diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied .The Brinell scale / b r ə ˈ n ɛ l / characterizes the indentation hardness of materials through the scale of penetration of an indenter, loaded on a material test-piece. It is one of several definitions of hardness in materials science.The resulting indent is measured by either the depth of penetration or the dimensions of the resulting indentation. Hardness testing plays a vital role in materials testing, quality control, and component acceptance. . Rockwell .

Get all the information you need on hardness testing and hardness test methods from ZwickRoell! Definition Examples Products for hardness testing More information . J. A. Brinell develops a ball indentation test that later . Softer materials like thermoplastics will need lower loads to produce an appropriately-sized indentation. Loads of Different Hardness Test Methods. Each hardness testing method has a range of loads that are .

ASTM E10 defines the Brinell hardness test as an indentation hardness test performed in a verified machine by forcing a tungsten carbide indenter into the test material surface. 2. Brinell Hardness Test Procedure . Rockwell (HRB)- 100Kg 1/16″ Ball: Vickers Hardness (HV)- Diamond Pyramid 120 Kg:

rockwell hardness testing guide pdf

rockwell hardness scale for plastic

paint test kit

If the indentation diameters are too large and lie in the range of the test ball diameter, the test ball is pressed too deeply into the material. A further penetration then hardly produces a larger indentation diameter, which then leads to no longer reproducible hardness values due to measurement inaccuracies in the diameter determination.An indentation hardness test using a verified machine to force a diamond spheroconical indenter or tungsten carbide (or steel) ball indenter, under specified conditions, into the surface of the material under test, and to measure the difference in depth of the indentation as the force on the indenter is increased from a specified preliminary . In a typical test, the diameter of the ball d = 10 mm and the applied load P = 3000 kgf (~29.4 kN). Smaller loads of P = 1500 kgf (~14.9 kN) and . Cagliero R (2016) Instrumented indentation test: in the macro hardness range. LAP Lambert Academic Publishing. Google Scholar Handadi UP, Udupa KR (2017) Indentation creep studies on stainless .

In the Rockwell hardness test, the measure of the hardness is not an indentation surface but an indentation depth. Either a carbide ball or a rounded diamond cone with a tip angle of 120° and a tip radius of 0.2 mm serves as the indenter. The indentation depth can be read directly from a dial gauge via the traverse path of the testing machine. Ball-indentation hardnessThe Ball Indentation Hardness test (ISO 2039-1; DIN 53456) is used in Europe much more often than in North America. The Barcol hardness test is sometimes chosen for thermoset polymers. The figure below, from Mitsubishi Chemical Advanced Materials , shows the Rockwell hardness test geometry.

Automated Ball Indentation (ABI) technique has the potential to evaluate tensile and fracture properties of materials by testing a small volume of material. ABI testing involves various parameters such as surface finish of test specimen, maximum depth of indentation, number of loading-unloading cycles and material of indenter. As ABI test is yet to be .GB/T 3854-2017 Test method for hardness of reinforced plastics by means of a Barcol impresser增强塑料巴柯尔硬度试验方法. 球压痕硬度Ball indentation hardness. ISO 2039-1:2001 Plastics - Determination of Hardness - Part 1: Ball Indentation Method. GB/T 3398.1-2008 塑料.硬度的测定.第1部分:球形压痕法

The ball indentation hardness determined by this method may provide data for research and development, quality control and acceptance or rejection under specifications. 2 Normative reference The following normative document contains provisions which, through reference in this text, constitute provisions of this part of ISO 2039 .

Ball indentation hardness = Applied load/Surface area of impression . the test. The diameter of the ball shall be (5,0 ± 0,05) mm. 5.2 Timing device, accurate to ± 0,1 s 6 Test specimens Each test specimen shall be a smooth flat sheet or block of .The first widely accepted and standardized indentation-hardness test was proposed by J. A. Brinell in 1900. The Brinell hardness test consists in indenting the metal surface with a 10-mm-diameter steel ball at a load of 3,000 kg mass (∼29400 N). . This angle was chosen because it approximates the most desirable ratio of indentation diameter . The ball indentation test is performed and combined with the energy method by using various changed mechanical properties of 316L austenitic stainless steel under different elongations. The investigated results indicate that the material mechanical properties and the micro-indentation morphological changes have evidently relevance.

The Brinell, Vickers, Meyer, Rockwell, Shore, IHRD, Knoop, Buchholz, and nanoindentation methods used to measure the indentation hardness of materials at different scales are compared, and main .The Ball Indentation Hardness test (ISO 2039-1; DIN 53456) is used in Europe much more often than in North America. The Barcol harness test is sometimes chosen for thermoset polymers. The figure below, from Quadrant . Engineering Plastic Products, shows the Rockwell hardness test geometry.Hardness tests that measure the depth of indenter penetration include: Rockwell, Instrumented Indentation Testing, and Ball Indentation Hardness Hardness tests that measure the size of the impression left by the indenter include: Vickers, Knoop, and Brinell Briefly stated, IIT is a nano-hardness test (NHT) for thin films and coatings while the Automated Ball Indentation ® (ABI ®) test is an accurate replacement of both the tensile and the fracture .

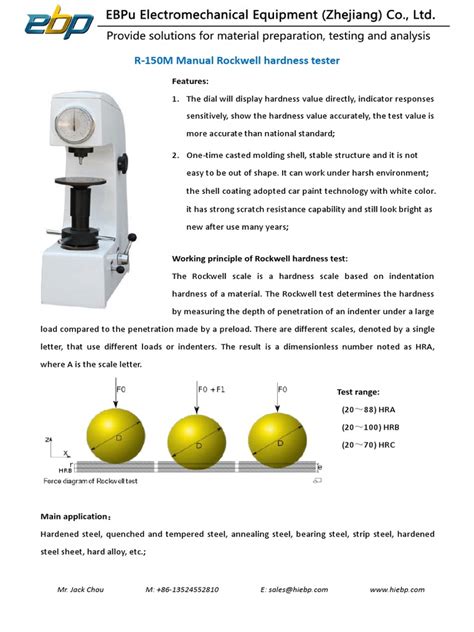

A Rockwell hardness tester. The Rockwell scale is a hardness scale based on indentation hardness of a material. The Rockwell test measures the depth of penetration of an indenter under a large load (major load) compared to the penetration made by a preload (minor load). [1] There are different scales, denoted by a single letter, that use different loads or indenters.

Achieve reliable test results with the ZHR150CL hardness tester - for more than 30 different depth-measurement applications, including Rockwell for metals and ball indentation hardness for plastics. Jump to the content of the page The Brinell hardness number (BHN or HBW) describes the hardness of a material. The higher the number, the harder the material. The Brinell hardness test involves pressing a small metal ball into the surface of the test material with a known amount of force. The resulting indentation is then measured and converted into a hardness number.

This part of ISO 2039 specifies a method for determining the hardness of plastics and ebonite by means of a. loaded ball indenter. The ball indentation hardness determined by this method may provide data for research and development, quality. control and acceptance or .ISO 2039-1:2001(E) PDF disclaimer This PDF file may contain embedded typefaces. In accordance with Adobe's licensing policy, this file may be printed or viewed but shall not

Brinell hardness test is an indentation hardness test.It uses a hard spherical ball (usually around 10mm in diameter). An applied force (a typical test will use 3,000 kilograms) pushes the ball against the surface of the material for a set amount of time (between 10 – 30 seconds, known as the dwell time).

oped a new indentation test for metals that were too hard to evaluate using the Brinell test. the hardened steel ball of the Brinell test limited the test to steels with hardnesses below ~ 50 hBS (~ 8 hrC). (the harder tungsten carbide ball was not available in 9 5. the WC indenter extends the Brinell test to metals up to 6 5

paint test kit bunnings

metal dented after hardness test

Localizado Em Rio do Sul , Endorfit Academia é a escolha certa para quem procura um centro de cross training. Oferece CrossFiit, Progressão de .

ball indentation hardness test|metal dented after hardness test